Fabulous Tips About How Do You Splice Wires Safely

The Lineman's Splice How To Make Reliable Electrical Connections In

Understanding the Basics of Wire Splicing

1. Why Safe Wire Splicing Matters

Ever wondered what keeps your lights on and your devices humming? It all comes down to the magic of electricity flowing through wires. But what happens when a wire breaks or you need to extend one? That's where wire splicing comes in! However, messing with electricity can be a bit like wrestling a grumpy badger — you need to know what you're doing to avoid getting nipped (or worse!). Ignoring safety protocols can lead to shocks, fires, and a whole lot of regret. So, before you even think about touching those wires, let's get clear on why safety is paramount. We're talking about protecting yourself, your family, and your property.

Wire splicing isn't just about twisting two wires together and hoping for the best. It's a skill that requires knowledge, the right tools, and a healthy dose of caution. A poorly spliced wire can create a weak connection, leading to overheating, sparks, and potentially a fire hazard. Nobody wants their home turning into an impromptu bonfire, right? So, let's dive into the essential techniques to ensure your wire splices are not only functional but also super safe.

Think of your electrical system like the circulatory system of a house. Wires are the veins and arteries, and a bad splice is like a clogged artery. It restricts the flow and can cause serious problems down the line. By following the proper safety procedures and using the correct methods, you're ensuring the smooth flow of electricity and preventing potential disasters. It's like giving your home a healthy heart! Plus, doing it right the first time saves you time, money, and a whole lot of headaches.

Safety begins long before you even pick up your wire strippers. It starts with understanding the electrical codes in your area and knowing what you're legally allowed to do yourself. Remember, some electrical work requires a licensed electrician, and attempting it yourself could lead to fines or, more importantly, put you and your home at risk. When in doubt, always consult a professional. It's better to be safe than sorry, especially when dealing with something as potentially dangerous as electricity.

Essential Tools and Safety Gear for Wire Splicing

2. Gathering Your Arsenal of Safety

Alright, you're ready to tackle some wire splicing? Fantastic! But before you even think about reaching for those wires, let's make sure you have the right tools and safety gear. Imagine trying to bake a cake without a mixing bowl or oven — it's just not going to work! The same goes for wire splicing. Having the proper equipment is essential for a safe and successful job. Think of it as assembling your electrical superhero toolkit.

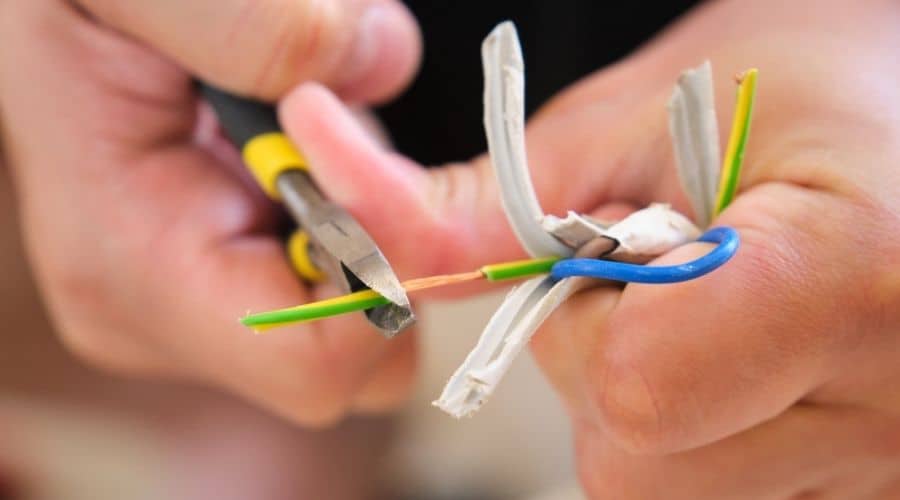

First up, you'll need a good set of wire strippers. These handy tools allow you to remove the insulation from wires without damaging the conductive core. Using a knife or other makeshift tool is a recipe for disaster, as you could easily nick the wire and weaken it. Invest in a quality pair of wire strippers that are designed for the gauge of wire you'll be working with. Trust me, your fingers will thank you.

Next on the list is a pair of lineman's pliers. These are your go-to tool for twisting wires together, cutting wires, and generally getting a good grip on things. Look for a pair with insulated handles to protect you from electrical shock. Remember, even when the power is off, it's always better to be safe than sorry. Consider it an extra layer of protection against any stray voltage.

Now, let's talk about safety gear. The most important item on this list is a pair of insulated gloves. These gloves will protect your hands from electrical shock. Make sure they are rated for the voltage you'll be working with. Eye protection is also crucial. Safety glasses or goggles will prevent any debris from getting into your eyes while you're stripping or cutting wires. And finally, a non-contact voltage tester is a must-have. This device allows you to check if a wire is live without actually touching it. It's like having a sixth sense for electricity!

How To Splice Electrical Wires Safely & Securely

Step-by-Step Guide to Splicing Wires Securely

3. The Art of the Perfect Splice

Okay, you've got your tools, you're wearing your safety gear, and you're ready to splice some wires! But hold on a sec. Before you start twisting and turning, let's walk through the process step-by-step to ensure a safe and reliable connection. Think of it like following a recipe. If you skip a step or add the wrong ingredient, the final result might not be quite what you expected. So, pay attention and let's get splicing!

First things first, always turn off the power! This might seem like a no-brainer, but it's worth repeating. Go to your breaker box and flip the switch that controls the circuit you'll be working on. To be extra cautious, use your non-contact voltage tester to confirm that the wires are indeed dead. There's no such thing as being too careful when it comes to electricity. Consider it your pre-flight check before taking off on your electrical adventure.

Next, strip the insulation from the ends of the wires you'll be splicing. Use your wire strippers to remove about 3/4 inch of insulation. Be careful not to nick the wire itself. A clean, undamaged wire is essential for a strong connection. Now, twist the bare wires together tightly. Use your lineman's pliers to get a good, solid connection. The wires should be intertwined and secure, creating a mechanical bond.

Finally, it's time to insulate the splice. The best way to do this is with a wire connector, also known as a wire nut. These little plastic caps screw onto the twisted wires and provide a secure, insulated connection. Make sure you use the correct size wire connector for the number and gauge of wires you're splicing. Twist the wire connector onto the wires until it's snug. Give it a gentle tug to make sure it's securely in place. And that's it! You've successfully spliced two wires together safely and securely. Now wasn't that easier than you thought?

How To Splice Wires For Electricians YouTube

Common Mistakes to Avoid During Wire Splicing

4. Dodging the Pitfalls of Electrical Work

Even with the best intentions and the right tools, it's easy to make mistakes when splicing wires. These mistakes can range from minor inconveniences to serious safety hazards. So, let's take a look at some common pitfalls to avoid to ensure your wire splices are top-notch. Think of it like learning from the mistakes of others so you don't have to make them yourself!

One of the most common mistakes is not turning off the power. We've already stressed this, but it's so important that it bears repeating. Working on live wires is incredibly dangerous and can lead to serious injury or even death. Always double-check that the power is off before you start working. It's not worth the risk, no matter how tempting it might be to skip this step. Consider it the golden rule of electrical work.

Another common mistake is using the wrong size wire connector. Wire connectors are designed for specific gauges and numbers of wires. Using a connector that's too small can result in a loose connection, while using one that's too large can leave the wires exposed. Always check the packaging to ensure you're using the correct size connector for your application. It's like wearing shoes that are the wrong size — uncomfortable and potentially dangerous.

Stripping too much or too little insulation is another frequent error. If you strip too much insulation, the bare wire will be exposed, creating a potential shock hazard. If you don't strip enough insulation, the connection will be weak and unreliable. Aim for about 3/4 inch of bare wire, and make sure the insulation is clean and undamaged. Think of it as finding the Goldilocks zone of wire stripping — not too much, not too little, just right.

Finally, failing to properly secure the wire connector is a common mistake. The wire connector should be twisted onto the wires until it's snug and secure. Give it a gentle tug to make sure it's not going to come loose. A loose wire connector can lead to a faulty connection and potentially a fire hazard. It's like tightening the lug nuts on your car's tires — you want to make sure they're nice and secure.

How To Splice Two Electrical Wires Together

Advanced Techniques and Best Practices

5. Elevating Your Splicing Game

So, you've mastered the basics of wire splicing and you're feeling like a seasoned pro? That's fantastic! But there's always more to learn. Let's explore some advanced techniques and best practices that will take your wire splicing skills to the next level. Think of it as leveling up in your electrical expertise!

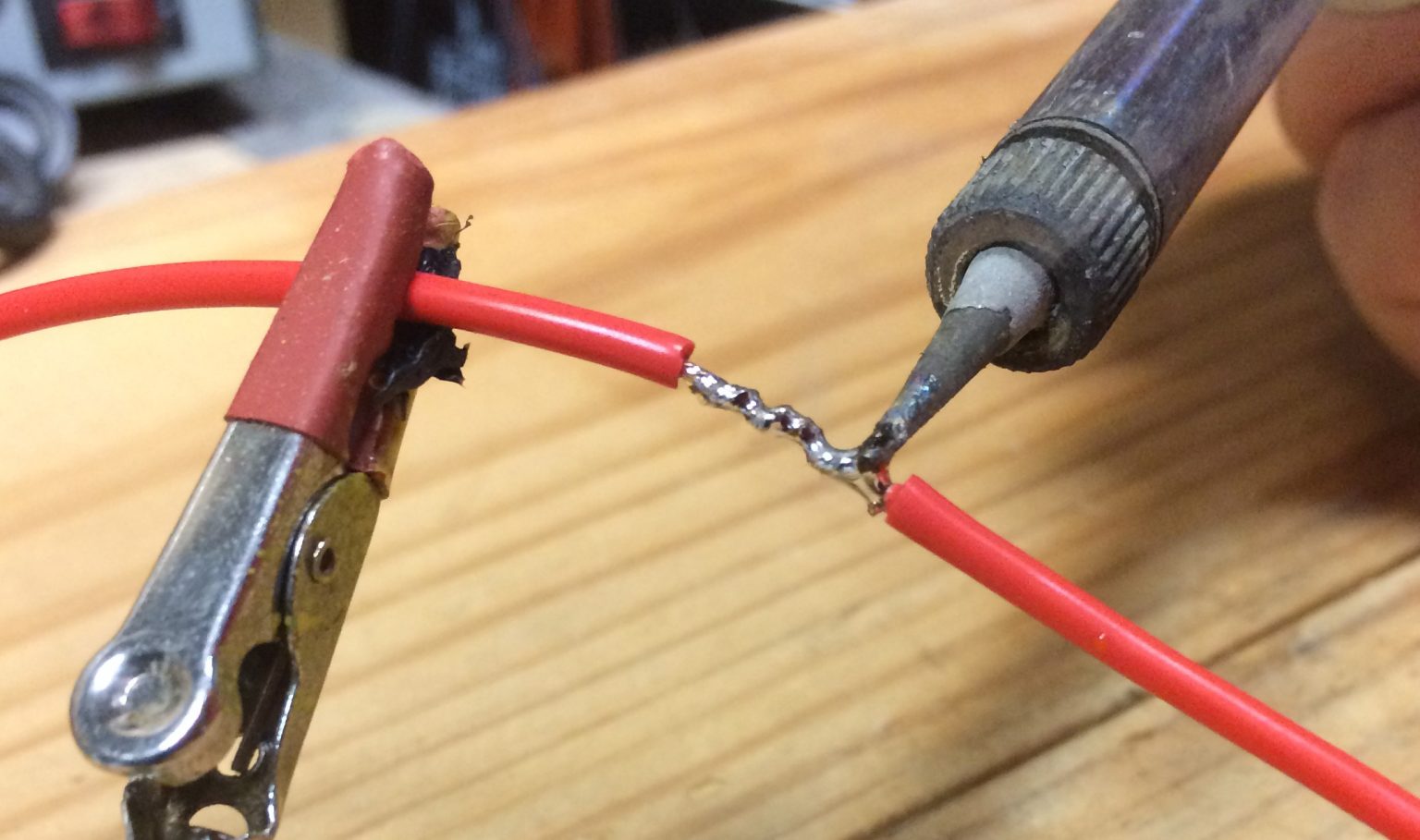

One advanced technique is using soldering to create a more permanent and reliable connection. Soldering involves melting solder onto the twisted wires to create a solid, conductive bond. This is particularly useful for applications where vibration or movement could cause a traditional wire connector to loosen. However, soldering requires specialized equipment and skills, so it's not for the faint of heart. Consider it the black belt of wire splicing techniques.

Another best practice is to always use the correct type of wire for the application. Different types of wire are designed for different purposes. For example, solid-core wire is typically used for permanent installations, while stranded wire is more flexible and better suited for applications where the wire might be bent or moved. Using the wrong type of wire can lead to problems down the road. It's like using the wrong tool for the job — it might work in a pinch, but it's not ideal.

When splicing wires in a junction box, always make sure to leave enough slack in the wires. This will allow you to easily make connections and troubleshoot problems in the future. It's also important to keep the wires organized and neatly arranged in the junction box. This will make it easier to work on the wires and reduce the risk of accidentally damaging them. Think of it as keeping your electrical workspace tidy and efficient.

Finally, always double-check your work before you close up the junction box. Make sure all the connections are secure, the wire connectors are properly installed, and the wires are neatly arranged. Once you're satisfied that everything is in order, you can safely close up the junction box and restore power to the circuit. It's like giving your electrical work a final inspection before signing off on the project.

FAQ

6. Clearing Up Common Confusions

Still have some lingering questions about wire splicing? No problem! Let's tackle some frequently asked questions to clear up any remaining confusion. Think of it as your personal wire splicing Q&A session.

Q: Can I splice different gauges of wire together?

A: It's generally not recommended to splice different gauges of wire together, as this can create a bottleneck in the circuit and lead to overheating. If you must splice different gauges of wire, use a wire connector that is specifically designed for this purpose.

Q: What's the difference between solid-core wire and stranded wire?

A: Solid-core wire consists of a single, solid strand of copper, while stranded wire consists of multiple, thin strands of copper twisted together. Solid-core wire is typically used for permanent installations, while stranded wire is more flexible and better suited for applications where the wire might be bent or moved.

Q: How do I know what size wire connector to use?

A: The size of the wire connector depends on the number and gauge of the wires you're splicing. Check the packaging of the wire connector for information on its capacity. If you're not sure, it's always better to err on the side of caution and use a larger connector.

Q: Is it okay to use electrical tape instead of wire connectors?

A: While electrical tape can provide some insulation, it's not a substitute for wire connectors. Wire connectors provide a more secure and reliable connection and are much less likely to come loose over time. Electrical tape should only be used as a supplemental form of insulation, not as the primary means of securing the connection.